A Reddit post titled "Heat pumps f***ing suck" recently collected over 500 comments in less than a week. Technicians piled on. Homeowners vented. The frustration was real.

The diagnosis, however, was wrong.

The Uncomfortable Math

Here's a statistic that should make you pause before blaming your equipment: 70-90% of residential HVAC systems have at least one performance-compromising fault (U.S. Department of Energy, 2018). When duct leakage is factored in, that figure climbs to 90-100%.

Read that again. Your HVAC system is statistically more likely to be improperly installed than functioning correctly. The industry has somehow normalized a failure rate that would bankrupt any other manufacturing sector.

Heat pumps exacerbate this dysfunction. A 2024 analysis found that while heat pumps represent only 14% of the residential HVAC market, they account for 39% of total energy waste from installation faults, roughly 8 terawatt-hours annually (ACEEE, 2024).

That's not because heat pumps are fragile technology. It's because heat pumps are precise technology being installed by people who learned on forgiving technology.

A gas furnace will burn fuel at roughly the same rate whether the ductwork is adequate or laughable. A heat pump is a dynamic system that depends on the precise pressure-enthalpy relationship of the refrigerant cycle. The shortcuts that a furnace shrugs off will bring a heat pump to its knees, and the homeowner to Reddit.

Watch: Do Heat Pumps Work in Cold Climates? YES — Here's Why! (July 2025)

The Four Horsemen of Heat Pump Failure

The DOE's research identifies four categories of installation faults that drive this performance gap. None of them involve defective compressors or fundamentally flawed thermodynamics. All of them involve humans cutting corners.

Refrigerant Charge

Between 50-72% of systems have incorrect charge, according to field studies (Pacific Northwest National Laboratory). Undercharge starves the evaporator, tanks capacity, and accelerates frost formation. Overcharge drives up head pressure and can cause liquid slugging. Both scenarios make you question whether the technology "works." The technology works fine; it's just suffocating on incorrect fluid dynamics.

Airflow

The traditional rule of 400 CFM per ton was developed for conventional air conditioners. Heat pumps, particularly modern inverter-driven systems, have different requirements that vary by manufacturer and operating mode. Variable-speed systems automatically modulate airflow along with compressor speed, which means the "400 CFM/ton" shorthand no longer applies the way it once did (ACCA, 2024). What matters is whether the installer verified airflow against the manufacturer's actual specifications. Field measurements routinely find systems operating well below those specifications. On a heat pump in heating mode, restricted airflow causes the system to protect itself by ramping down compressor speed, which you experience as "blowing lukewarm air." The heat pump is being throttled by the ductwork, not by physics.

Duct Leakage

The most ubiquitous fault, and arguably the most insidious. Supply leaks vent conditioned air into attics and crawlspaces. Return leaks pull in extreme temperatures and contaminants. Either way, the load calculation that (hopefully) existed becomes fiction. You're paying to heat and cool spaces you'll never occupy.

Sizing Errors

A study of high-performance homes found an average cooling load of 1,431 square feet per ton (University of Illinois SEDAC, 2021). Contractors using the "one ton per 500 square feet" rule of thumb (which has no basis in building science) would oversize that system by nearly 300%. Modern inverter units can modulate down, but they still have a minimum capacity. Below that threshold, they cycle on and off like the single-stage equipment they were supposed to replace.

"We're seeing close to 40% of heat pumps undercharged or leaking. No wonder callbacks are high."

Brendan Hermalyn, Thalo Labs, on the Building HVAC Science Podcast (October 2025)

Cold Climate Performance: The Technology Isn't the Problem

The persistent belief that heat pumps "don't work below 30°F" is a relic of R-22 systems that should have been retired with the technology itself.

Tech Advancements: Cold-Climate Heat Pumps - YouTube

Modern cold-climate heat pumps use vapor injection to maintain capacity at temperatures that would have been science fiction a decade ago. The physics is elegant: divert a portion of liquid refrigerant, expand it to intermediate pressure, inject it into the compressor scroll. The result is internal cooling and boosted mass flow, allowing the unit to maintain heating capacity even when the outdoor coil is surrounded by arctic air.

Here's what manufacturers have actually verified:

| Manufacturer | Model Line | Rated Low Temp | 100% Capacity At |

|---|---|---|---|

| Mitsubishi | H2i Plus | -22°F | 5°F |

| Daikin | Aurora | -13°F | 5°F |

| LG | RED | -13°F (operates to -31°F) | 5°F |

| Carrier | Infinity | -22°F | 5°F |

| Fujitsu | XLTH+ | -22°F | -15°F |

| Midea | EVOX G3 | -22°F | -13°F |

| Bosch | IDS Ultra | -13°F | 5°F |

The technology works. The question is whether your installation allows it to.

Watch: What to Know Before Switching to Whole House Heat Pumps — Ask This Old House

The Balance Point Confusion

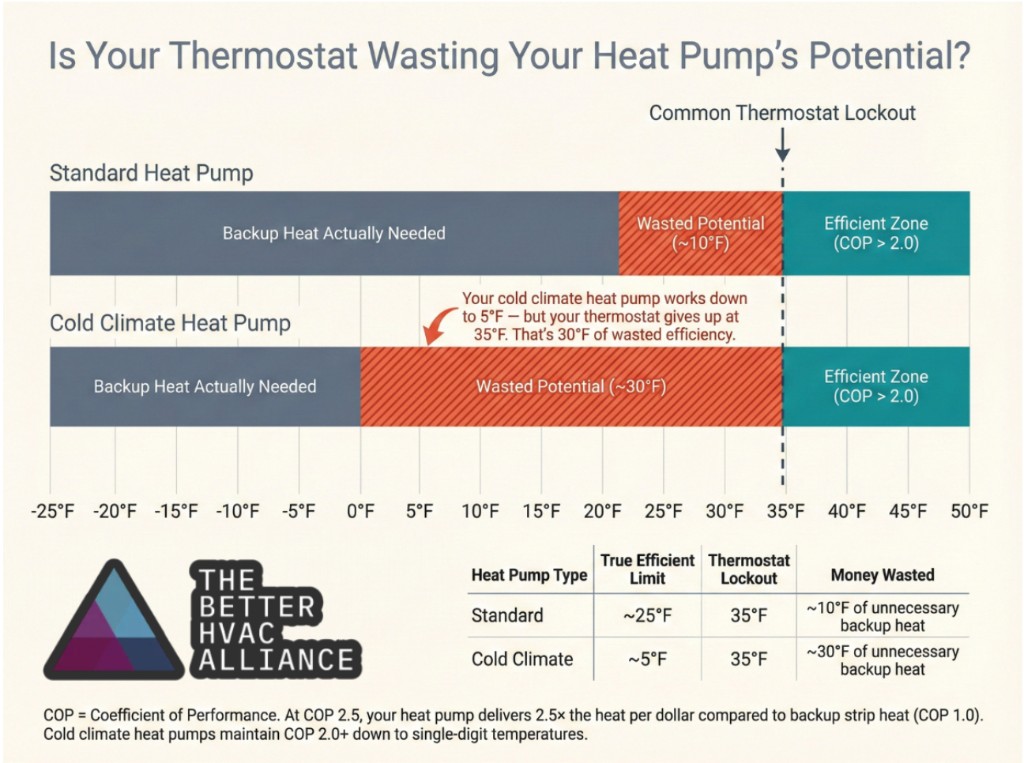

If your energy bill tripled after installing a heat pump, ask one question first: What temperature is your heat pump locking out?

Many legacy thermostats are programmed with a 35°F lockout, a setting from an era when heat pumps couldn't efficiently operate below that threshold. At 35°F, the system hands off to auxiliary strip heat (COP of 1.0) or a gas furnace, regardless of whether the heat pump could have carried the load.

Modern cold-climate units maintain a COP above 2.5 well into the single digits. If your system switches to strip heat at 35°F, you're paying three times more than necessary for every degree between 35°F and the actual thermal balance point. Multiply that by a cold winter, and the "scam" narrative writes itself, even though the equipment was never given a chance to perform.

The economic balance point (where operating cost favors backup heat) and the thermal balance point (where the heat pump physically cannot meet the load) are often 20-30 degrees apart. That gap is money leaving your wallet through incorrect configuration. The installer who doesn't understand the difference between these two concepts is the installer who set you up for disappointment.

What You Can Do About It

The solution isn't better equipment. It's verification.

A proper commissioning report documents static pressure, measured airflow, and weighed refrigerant charge. It transforms a "he said, she said" complaint into a conversation about what was actually installed and whether it meets manufacturer specifications.

The challenge? Most homeowners have no way to verify whether their system was installed correctly. You can't see refrigerant charge. You can't feel static pressure. You trust that the contractor did it right because they told you they did.

This is where data-driven contractors differentiate themselves. Tools like measureQuick's HVAC Vitals™ provide homeowners with a health score (0-100%) and detailed documentation of system performance, similar to bloodwork from your doctor. Instead of "it seems fine," you get measured values compared against manufacturer specifications.

The difference between a 70% system and a 95% system might not be obvious on a mild day. But it shows up in your utility bill, your comfort on the coldest night of the year, and the lifespan of equipment that cost you $15,000 or more.

Find a Contractor Who Measures

The heat pump isn't the problem. The process is.

The BetterHVAC Alliance connects homeowners with HVAC professionals who have committed to ethical, data-driven practices. These contractors pledge to continuous learning, excellence through measurement, and transparency in their work.

If you're installing a new heat pump, replacing existing equipment, or simply want to verify that your current system is performing as designed, start with a contractor who can prove their work with data.